PS-SEAL®

PTFE based high performance seal / Rotary Shaft Seals

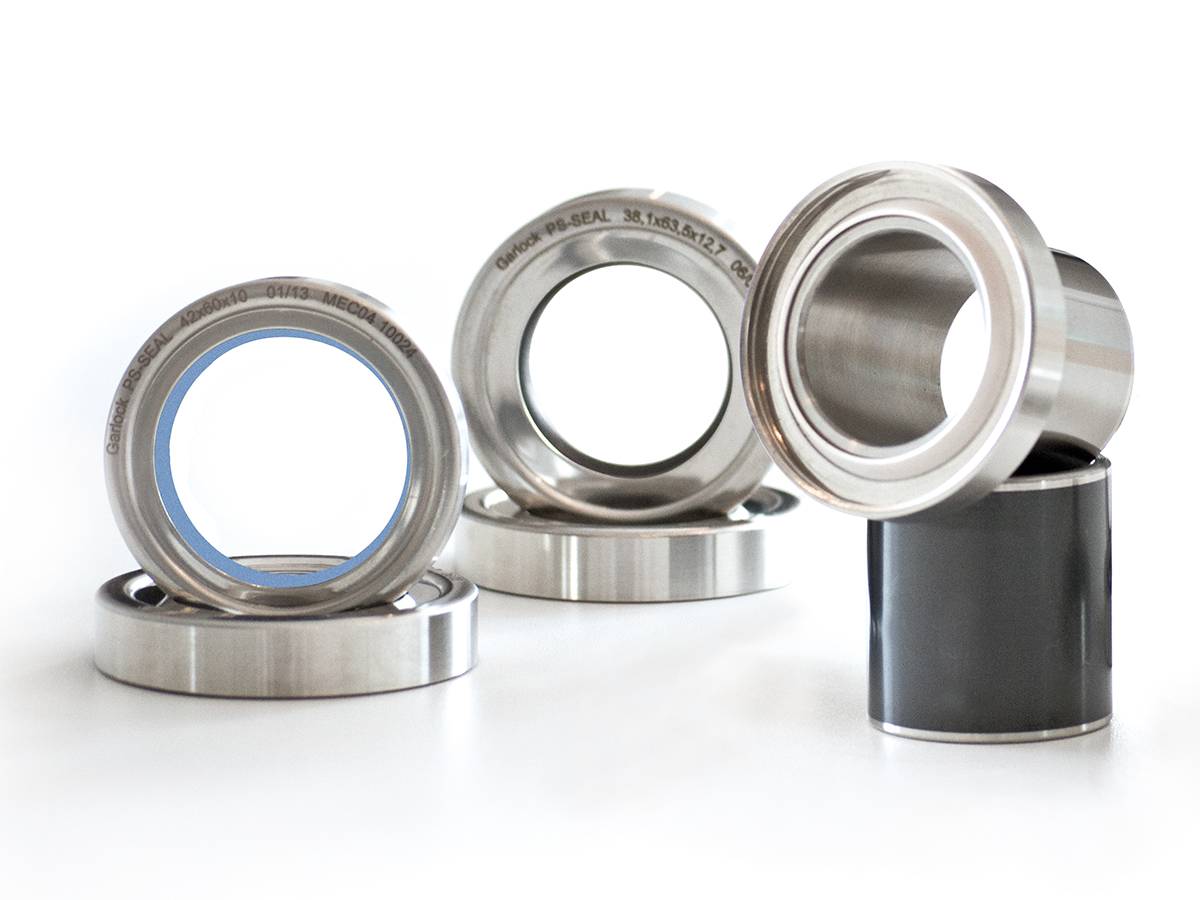

The PS-SEAL® product line stands for reliable sealing of rotating shafts at high circumferential speed, high pressure and extreme temperatures. Abrasive media is sealed as well as aggressive media. Radial shaft seals typically do not perform well under these conditions as their seal lips are made of elastomeric materials. PS-SEALs are used in many different applications and can also be an alternative to mechanical seals and braided packings. The product line PS-SEAL® offers cost-effective and practical solutions to a wide range of applications. The portfolio of Garlock shaft seals offers standardized as well as special customized seals. The high performance seals PS-SEAL® work with a sealing lip made of GYLON® or other modified PTFEs. Garlock produces GYLON® in a process that has been specially developed.

PS-SEAL® Standard is a Garlock shaft seal consisting of a stainless steel (1.4571) case, a GYLON® Black seal lip and a static sealing element made of FKM (maximum 10 bar, maximum 205°C, no FDA).

PS-SEAL® Non-Standard are shaft seals in standard sizes with different configurations of their seal lips, different lip materials and different materials of their static sealing element. The PS-SEAL® Non-Standard offers an economic way of producing special configurations appropriate to your needs, as it is based on the standard version.

PS-SEAL® Special – due to the complex application of high performance seals, PS-SEAL® Standard and PS-SEAL® Non-Standard may not always provide the best solution for application-specific needs. That is why Garlock offers other sealing options with single and multiple lip assemblies. As far as practicable these seals are standardized to supply our customers with cost-efficient special solutions. We recommend consulting our specialists for the usage of these PS-SEAL® configuration options. PS-SEAL® Special is available in many different lip and housing materials.

Features & Benefits

- Useable under high pressure and in extreme vacuum

- Very suitable for high circumferential speed

- Excellent chemical resistance

- Useable in food and pharma applications (FDA)

- EN 1935/2004 certificate possible

- SIP/CIP compatible

- Good to excellent dry running capability

- Wear resistant and low friction

Specifications

Seal case

The standard material for the PS-SEAL® seal case is stainless steel 1.4571. Other materials can be supplied on request.

Operating Pressure

- PS-SEAL® Standard max. 10 bar

- PS-SEAL® Non-Standard max. 25 bar (depending on version)

- PS-SEAL® Special max. 25 bar (depending on version)

- PS-SEAL® Lip max. 25 bar (depending on version)

- PS-ProSet® max. 25 bar (depending on version)

For maximum pressure applications please check the p x v – value. Garlock recommends an axial fixation of the PS-SEAL® when it is used in applications under high pressure.

Temperature Range

The PS-SEAL® lip material can handle temperatures between –90 °C and +260 °C. Please note, that there is a difference between the temperature on the seal and the process-temperature due to the friction which releases additional energy/heat.

Material

GYLON® is being used as lip seal material of PS-SEAL® and significantly responsible for its successful operation. We offer highly diverse seal options and combinations of materials to cope with the very different requirements of many diverse industrial branches. GYLON® is a modified PTFE and is used due to its high chemical resistance, its high temperature range and its low friction.

Counter Surface

As the counter surface has a major impact on the efficiency and life-time of our seals, its configuration needs also to be considered. Garlock can offer an appropriate package of seal and counter surface (protection sleeve) to provide an optimal and durable sealing solution. For an optimal interaction between sealing and abrasion the following surface characteristics should be complied with:

Surface Abrasiveness

Ra = 0,1 – 0,4 μm

Rz = 0,6 – 2,0 μm

Rmax = 4 μm

The running surface may not have a helical spiralling indentations as the arising conveying effect could cause leakage.

Surface Hardness

60 HRC

Under high stress (p x v – value) of more than 20 bar x m/s Garlock recommends an untwisted machined chromium oxide coating. Suitable coatings can be ordered from Garlock. Please consider a hard enough basic material when using micro-coatings.

Materials

| Lip Material | Ingredients | Properties |

| GYLON® Black | graphite |

|

| GYLON® White | barium sulfate |

|

| GYLON® Blue | glass-microspheres |

|

| F | econol |

|

| MS | molybdenum disulfide |

|

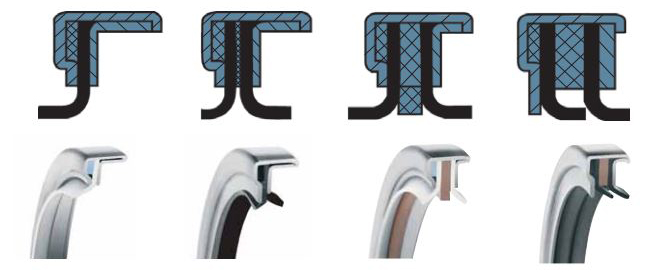

Non-Standard Configurations

Reverse lip | Single lip with dust lip | Back to back | Tandem

Downloads

- Letter of conformity EC1935/2004, EC10/2011

- Declaration FDA Conformity PS-SEAL

- Declaration of Conformity FDA – Coating

- Certificate TA-Luft for lip material F with barrier

- Declaration Restricted Phathalates Conformity for PS-SEAL

- Declaration of Conformity REACH and RoHS

- ADI – Declaration Animal Derivatives Ingredients for PS-SEAL

Technical Statements

- PS-SEAL® – PTFE based high performance seal – (YouTube Link)

- Garlock PS-SEAL® Installation Instruction (German with English subtitles) – (YouTube Link)

- PS-SEAL® Standard – (YouTube Link)

- PS-SEAL® Non-Standard – (YouTube Link)

- PS-SEAL® Non-Standard Configurations – (YouTube Link)

- PS-SEAL® – Case Study – Mixers for Food & Pharma (YouTube Link)

- PS-SEAL® – Case Study – Snack Production Process (YouTube Link)

Falkenweg 1

41468 Neuss

Germany

+49 2131 349-0

garlockgmbh @ garlock.com

© 2024 Garlock GmbH, Germany

Garlock Global Website

www.garlock.com

Career Site Europe

https://www.garlock-karriere.de/en