GYLON BIO-LINE® / GYLON BIO-LINE® PLUS

Process and equipment reliability

Pharmaceutical and food processing industries strive to limit and avoid operational down time caused by cleaning and maintenance procedures. Sterilization cycles are carried out in the shortest possible time with highly concentrated chemicals, high temperatures and increased flow rates. Exposed to these conditions elastomeric seals fail due to exceeding their limits, thus resulting in short exchange intervals. GYLON BIO-LINE® and GYLON BIO-LINE ® PLUS offer approved sealing materials for high temperatures and demanding processes – while at the same time entirely compliant to all major food and pharmaceutical regulations.

When seeking materials resistant to acids, caustics and sensitive media, performing at demanding temperatures and pressures, established options are hardly present. The available elastomers generally fail in at least one of these requirements and conventional PTFE is not suitable due to its cold flow properties. The modified and restructured PTFE of the GYLON BIO-LINE® as well as the restructured PTFE of the GYLON BIO-LINE® PLUS are well-proven in the industries to meet all these criteria since many years. Not only providing safe and economical processes but also optimizing stock keeping.

GYLON BIO-LINE®

GYLON BIO-PRO®

GYLON BIO-PRO® seals offer a safe solution with its modified and restructured PTFE material, pre-formed and stress controlled, for all TRI-CLAMP standards. It is dimensionally stable and resists intrusion into the pipe bore. Can be safely used with all cleaning, neutralizing and sterilizing media, including steam, and for all standard process temperatures.

Features & Benefits

-

High dimensional stability

-

Stopped cold flow

-

No intrusion/recession

-

No gap extrusion

-

Excellent chemical resistance

-

Masters all CIP- and SIP-cleaning processes

-

Excellent cleanability of gasket

-

Wide temperature range

-

High pressure & vaccum duties

Specifications

- Temperature: -268 °C to +260 °C

- Pressure: up to 55 bar

- Filler: Aluminosilicate microspheres

GYLON BIO-ECO®

The necessity for adequate sealing stress and simultaneous recovery makes GYLON BIO-ECO® the ideal solution for

couplings in accordance with DIN 11851 and SMS1149. All of the disadvantages associated with current elastomeric seals regarding temperature, chemical resistance and re-usability are eliminated by the modified PTFE material.

Features & Benefits

-

High dimensional stability

-

Stopped cold flow

-

No intrusion/recession

-

No gap extrusion

-

Excellent chemical resistance

-

Masters all CIP- and SIP-cleaning processes

-

Excellent cleanability of gasket

-

Wide temperature range

-

High pressure & vacuum duties

Specifications

- Temperature: -268 °C to +260 °C

- Pressure: up to 55 bar

- Filler: Aluminosilicate microspheres

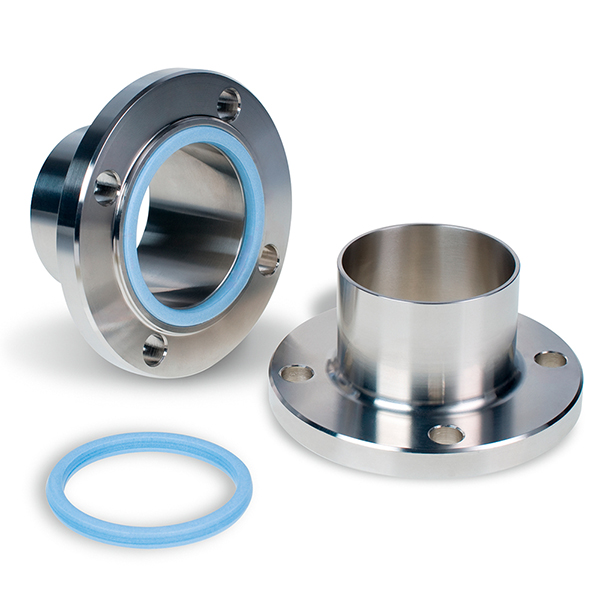

GYLON BIO-ASEPT®

GYLON BIO-ASEPT® seals offer high stability and a specific elasticity. The seals are pre-formed and stress controlled to provide a solid seal when assembled in the piping systems. Chemical degradation or brittleness will not occur under normal or even increasing process and sterilization conditions, due to specific, high performing PTFE sealing material.

Features & Benefits

-

High dimensional stability

-

Stopped cold flow

-

No intrusion/recession

-

No gap extrusion

-

Excellent chemical resistance

-

Masters all CIP- and SIP-cleaning processes

-

Excellent cleanability of gasket

-

Wide temperature range

-

High pressure & vacuum duties

Specifications

- Temperature: -268 °C to +260 °C

- Pressure: up to 55 bar

- Filler: Aluminosilicate microspheres

GYLON BIO-LOK®

Camlock connections are the standard connection for quick coupling in the food industry as well as the chemical industry. GYLON BIO-LOK® is made of highly compressible and flexible material GYLON® Style 3504. The seals offer a high stability and provide a solid seal when assembled.

Features & Benefits

-

High dimensional stability

-

Stopped cold flow

-

No extrusion, no cold flow, high recovery

-

Centered by outer ring

-

Higher flexibility for open/close processes

-

Temperature resistant

- Chemical resistant

Specifications

- Temperature – 210 °C to +260 °C

- Pressure up to 10 bar

GYLON BIO-LINE® PLUS

GYLON BIO-PRO® PLUS

GYLON BIO-PRO® PLUS is a high performance gasketing product made out of 100% pure PTFE with an excellent dimensional stability. Because of the excellent hygienic design of the gasket cleaning processes can be carried out effectively and resource efficiently. Therefore it is especially suited for the Pharma- and Food industries.

Features & Benefits

-

3-A Certified / Smooth surface (20-27)

-

Hygienic Design

-

Excellent cleanability of gasket (EHEDG Doc.2)

-

Traceability via batch number

-

High dimensional stability

-

Stopped cold flow

-

No intrusion/recession

-

No gap extrusion

-

Excellent chemical resistance

-

Masters all CIP- and SIP-cleaning processes

-

Wide temperature range

Specifications

- Temperature: -268 °C to +260 °C

- Pressure: up to 55 bar

- 100% pure PTFE (no filler)

GYLON BIO-ECO® PLUS

Due to a restructured 100% PTFE in conjunction with an ultra smooth surface GYLON BIO-ECO® PLUS provides unrivaled sealing and cleaning characteristics for the most critical process applications. Inhibited cold flow as well as almost universal chemical resistance provide a reliable solution for the most demanding production lines in the pharmaceutical industry.

Features & Benefits

-

High dimensional stability

-

Stopped cold flow

-

No intrusion/recession

-

No gap extrusion

-

Excellent chemical resistance

-

Masters all CIP- and SIP-cleaning processes

-

Excellent cleanability of gasket

-

Wide temperature range

-

High pressure & vacuum duties

Specifications

- Temperature: -268 °C to +260 °C

- Pressure: up to 55 bar

- 100% pure PTFE (no filler)

GYLON BIO-ASEPT® PLUS

GYLON BIO-ASEPT® PLUS provides the highest industrial safety regarding resilience in operation. Due to its unique

gasket shape, which is designed to adapt to the flange geometry, it seals perfectly even under drastic conditions. Its smooth surface prevents germs from attaching and increasing.

Features & Benefits

-

High dimensional stability

-

Stopped cold flow

-

No intrusion/recession

-

No gap extrusion

-

Excellent chemical resistance

-

Masters all CIP- and SIP-cleaning processes

-

Excellent cleanability of gasket

-

Wide temperature range

-

High pressure & vacuum duties

Specifications

- Temperature: -268 °C to +260 °C

- Pressure: up to 55 bar

- 100% pure PTFE (no filler)

Downloads

- Declaration of Conformity FDA

- Letter of Conformance – Animal Derivates Ingredients – ADI

- Declaration of Conformity – Phthalate free, Bisphenol free

DIN EN 13555

FOOD SAFE – EC1935/2004, EC 10/2011 conformity

TA Luft

Falkenweg 1

41468 Neuss

Germany

+49 2131 349-0

garlockgmbh @ garlock.com

© 2024 Garlock GmbH, Germany

Garlock Global Website

www.garlock.com

Career Site Europe

https://www.garlock-karriere.de/en